3D Printing in Civil Engineering, also known as additive manufacturing, is a revolutionary technology that is transforming various industries, including civil engineering. This innovative approach involves creating three-dimensional objects by adding material layer by layer, based on digital models. In civil engineering, 3D printing holds immense potential to enhance design flexibility, reduce construction time, lower costs, and minimize waste. Let’s find out how 3D printing is unlocking new possibilities in civil engineering.

The Basics of 3D Printing

Before exploring its applications in civil engineering, it is essential to understand how 3D printing works. The process begins with a digital design created using computer-aided design (CAD) software. This design is then converted into a format that the 3D printer can understand, usually a file type like STL (stereolithography).

The 3D printer reads the digital file and starts building the object layer by layer. Various materials can be used for 3D printing, including plastics, metals, concrete, and even specialized materials for specific applications. The technology allows for intricate designs that would be challenging or impossible to achieve with traditional construction methods.

Applications of 3D Printing in Civil Engineering

Construction of Buildings and Structures : One of the most exciting applications of 3D printing in civil engineering is constructing buildings and other structures. Traditional construction methods are often time-consuming and labor-intensive. However, 3D printing can significantly speed up the process and reduce labor costs.

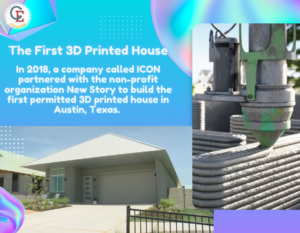

Case Study: The First 3D Printed House

In 2018, a company called ICON partnered with the non-profit organization New Story to build the first permitted 3D printed house in Austin, Texas. The 350-square-foot home was printed in just 48 hours at a cost of about $10,000. This project demonstrated the potential of 3D printing to provide affordable housing solutions quickly and efficiently.

Infrastructure Development : 3D printing is also making waves in the development of infrastructure. Bridges, roadways, and other critical infrastructure can benefit from this technology. The ability to create custom designs and components on-site can lead to faster project completion and more efficient use of materials.

Case Study: The World’s First 3D Printed Bridge

In 2018, the world’s first 3D printed pedestrian bridge was unveiled in Madrid, Spain. The bridge, made from concrete, spans 12 meters and was constructed using a large-scale 3D printer. This project showcased how 3D printing could be used to create complex and durable infrastructure.

Custom Components and Replacement Parts : Civil engineering projects often require custom components and replacement parts that are not readily available. 3D printing offers a solution by allowing engineers to create these parts on-demand, reducing downtime and costs.

Example: Custom Concrete Components

Using 3D printing, engineers can design and produce custom concrete components for specific projects. This capability is particularly useful for restoration and renovation projects, where matching existing architectural elements is crucial.

Sustainable Construction : Sustainability is a significant concern in modern construction. 3D printing can contribute to more sustainable practices by reducing material waste and enabling the use of recycled materials.

Example: Eco-Friendly Materials

Researchers are developing eco-friendly materials for 3D printing, such as recycled plastics and bio-based composites. These materials can be used to create sustainable building components, reducing the environmental impact of construction projects.

Disaster Relief and Emergency Housing : In disaster-stricken areas, providing quick and efficient housing solutions is critical. 3D printing can play a vital role in disaster relief by rapidly producing temporary shelters and emergency housing.

Case Study: Emergency Shelters

After natural disasters, 3D printing can be used to quickly construct temporary shelters for displaced populations. These shelters can be designed to be durable and weather-resistant, providing safe and secure housing during the recovery process.

Innovative Architectural Designs : Architects and engineers are constantly pushing the boundaries of design. 3D printing enables the creation of complex and innovative architectural designs that would be difficult to achieve with traditional methods.

Example: Complex Geometries

3D printing allows for the creation of complex geometries and intricate details in building facades and structures. This capability opens up new possibilities for creative and unique architectural designs.

Future Prospects

The future of 3D printing in civil engineering holds incredible potential, driven by ongoing advancements in technology, materials, and processes. As we look ahead, several key areas stand out where 3D printing is expected to make significant strides. These prospects promise to revolutionize the construction industry, bringing about more efficient, sustainable, and innovative practices.

New Materials

Better Building Materials: Scientists are creating new materials that are stronger, more durable, and better for the environment. These new materials will make 3D printed buildings and structures even better.

Smart Materials: Some new materials can change their properties in response to things like temperature or pressure. These smart materials can help buildings adapt to their environment.

Recycled Materials: Using recycled materials for 3D Printing in Civil Engineering can reduce waste and help protect the environment.

Automation and Robotics

Robots in Construction: Robots can be used to do 3D printing, working all day and night without getting tired. This can save time and reduce labor costs.

More Precise Building: Robots can print structures with very high precision, leading to less waste and better quality buildings.

Large-Scale Projects

Tall Buildings: In the future, we might see skyscrapers being built using 3D printing. This could make construction faster and cheaper.

Big Infrastructure Projects: 3D printing can be used for large projects like bridges and highways, making them quicker to build and more efficient.

Customized Solutions

Personalized Buildings: Architects will be able to design and print custom parts for buildings, making unique and creative designs possible.

On-Demand Production: Construction companies can print parts as they need them, reducing the need for large inventories and saving space.

Sustainable Practices

Less Waste: 3D printing uses only the materials needed for each part, which reduces waste compared to traditional construction methods.

Energy-Efficient Buildings: 3D printing can help create buildings that use less energy, making them better for the environment.

Innovative Designs

Complex Shapes: 3D printing allows for the creation of complex shapes and designs that are hard to make with traditional methods. This opens up new possibilities for architects and designers.

Built-In Features: In the future, buildings might be printed with electrical wiring, plumbing, and sensors already included, making the construction process faster and more efficient.

Education and Research

New Research: Universities and companies will work together to develop new materials and techniques for 3D printing, pushing the technology forward.

Training: People working in construction will need to learn new skills to use 3D printing technology effectively. Schools and training programs will need to teach these new skills.

Global Impact

Affordable Housing: 3D Printing in Civil Engineering can provide a quick and cheap way to build houses, especially in places where there is a housing shortage or after natural disasters.

Local Production: 3D Printing in Civil Engineering can be done locally, reducing the need for materials to be shipped long distances. This can lower costs and help the environment.

Challenges and Considerations

3D printing in construction holds a lot of promise, but it comes with some challenges and considerations. Finding the right materials that are strong and durable enough for building is essential. Ensuring that 3D printed structures are safe and meet all building codes requires thorough testing and collaboration with local authorities. The initial cost of 3D printing technology can be high, making it less accessible for some construction companies. Workers also need to learn new skills to operate the technology, which calls for updated training programs. Printing large structures efficiently is another hurdle, as is ensuring that these structures last as long as those built with traditional methods.

Finding the Right Materials: Not all materials are good for 3D printing. We need to find or develop materials that are strong and durable enough for building.

Making Sure Buildings are Safe: It’s important to make sure that 3D printed buildings and parts are strong and safe, especially for things like walls and supports. This means lots of testing and quality checks.

High Initial Costs: The machines and technology for 3D printing can be expensive to start with. Not every construction company can afford this.

Limited Access: In some areas, it might be hard to find or use 3D printing technology due to lack of resources or infrastructure.

Following Building Codes: Every place has rules and regulations for building. 3D printed structures need to meet these rules, which can be different in each area. This can be complicated and requires working with local authorities.

Learning New Skills: Construction workers and engineers need to learn how to use 3D printing technology. This means new training programs and education.

Printing Large Structures: Printing small items is easier than printing large buildings or bridges. Developing the technology to print larger structures efficiently is a big challenge.

Long-Term Performance: We need to ensure that 3D printed buildings and parts last as long as those made with traditional methods. This involves understanding how 3D printed materials behave over many years.

Eco-Friendly Practices: While 3D printing can reduce waste, the production of some materials and the operation of 3D printers can still impact the environment. Finding ways to make the entire process more eco-friendly is important.

Combining Old and New: Often, 3D printing will be used alongside traditional construction methods. Ensuring that these different methods work well together is another challenge.

Getting People on Board: It takes time for new technologies to be accepted and widely used. Convincing people in the construction industry to adopt 3D printing can be slow.

3D Printing in Civil Engineering can reduce waste, the production and operation processes still need to be made more eco-friendly. Integrating 3D printing with traditional construction methods and getting widespread industry acceptance will also take time. Despite these challenges, addressing them will help make 3D printing a standard part of future construction practices.

The future of 3D printing in civil engineering looks very bright. It promises to make building faster, cheaper, more sustainable, and more creative. As technology advances, we can expect to see 3D printing play a bigger role in how we construct everything from homes to highways.

Feel free to follow us there on Instagram and drop a comment to say hello!